Anuga FoodTec: Process Simulation with MESHFREE

Innovative Simulation for the Food Industry

Whether cleaning, stirring, kneading or injection processes – MESHFREE can be used to reliably simulate food technology processes. The software product developed by the Fraunhofer Institutes for Industrial Mathematics ITWM and for Algorithms and Scientific Computing SCAI uses grid-free simulations to map physical processes. This year, the institutes will again be represented at Anuga FoodTec from April 26 to 29 in Hall 7.1 at Stand A049.

The requirements in the food industry are diverse: from coatings to extrusion, forming, homogenization, and pressing processes – thanks to MESHFREE, material behavior in these applications can be simulated without any problems. One example is the filling of a beer glass, where foam formation presents a particular challenge for the simulation.

Here, MESHFREE combines the many years of expertise of the Fraunhofer Institutes ITWM and SCAI in simulating complex physical processes: The software product is based on a general material model, which can also be used to represent complex material behavior and can be handled with the numerical methodology.

Successful Cooperation

The two mathematical institutes work hand in hand: MESHFREE originated as a synthesis of two successful software packages and has been continuously developed since then. Fraunhofer SCAI is responsible for the highly efficient solution of the large systems of equations to be solved during the simulation and for performance optimization; Fraunhofer ITWM is in charge of the underlying numerical methodology for the precise simulation of the physical processes.

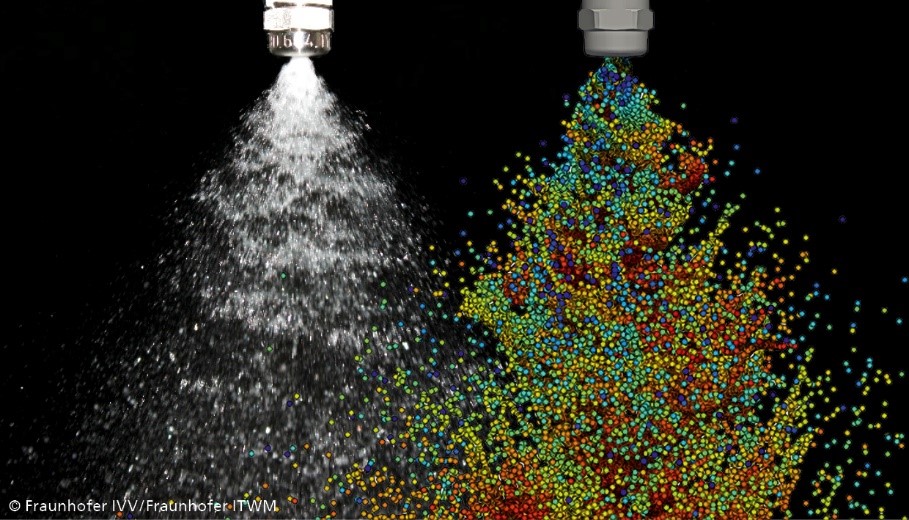

Currently, the ITWM focuses on the simulation of cleaning processes in the food industry. In the project »SpraySim«, which is funded by the German Federal Ministry for Economic Affairs and Climate Action, the researchers simulate cleaning liquid that reaches the surfaces via nozzles as a disintegrated spray jet.

Researchers from both Fraunhofer Institutes will be at the booth during the trade show days and will be available for questions and discussions.